3D-CPAM

3D Clothing Production by Additive Manufacturing (3D-CPAM) – An experiment inside CloudiFactoring Project

WHY 3D-CPAM

New era of fashion industry

There is currently a major effort in the development of Industrial 3D printing platforms, which will be transformed into 3D production environments supported by Cloud-HPC and represent new advanced industrial manufacturing technology. On that way 3D Clothing Production by Additive Manufacturing (3D CPAM) experiment is a brand new optimised, innovative production process with features of: flexibility, adaptability, integrability and full programmability but it limited with time required to produce a single product (e.g. a jacket) which significantly decreases the total efficiency of the manufacturing process.The optimization by speed-up of the production phase is therefore of the utmost importance in delivering the end products to the market. To overcome these bottlenecks 3D CPAM optimizing the 3D fashion design-manufacturing process by significantly reducing the production time combining modern industrial 3D printing technologies and advanced HPC/Cloud services.

On that way overcoming the constraints on product size and realization time that are evident as a barrier now. According to the above, this project proposes to use a Digital Factory Concept (DFC) using a new production platform – the Large Scale Industrial 3D Digital Printing Environment already developed by Mikrotvornica, an SME partner in this project proposal optimising for garment production in this experiment. 3D additive manufacturing or printing technologies have a major impact on the traditional supply chain by reducing the number of necessary steps, allowing more distributed and decentralized production (e.g., at the point of sale), and lowering the need for warehousing, packaging, and transportation. But several limitations are found during the process of clothing manufacturing 3D technology, these are related to the modelling programs, printing processes, the creation process and the wearing of the clothing. 3D CPAM project proposal focuses on optimizing the rendering programs and printing drive process, to reduce the time and cost of the manufacturing process.

3D-CPAM project focuses on optimizing the rendering programs and printing drive process, to reduce both the time-to-solution and the cost of the manufacturing process of 3D printed clothes

EXPERIMENT DESCRIPTION

Optimizing 3D fashion design-manufacturing process

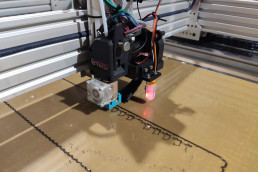

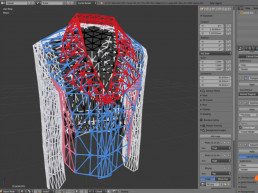

The additive manufacturing (3D printing) technologies have a major impact on the traditional supply chain by reducing the number of necessary steps, allowing more distributed and decentralized production (e.g., at the point of sale), and lowering the need for warehousing, packaging, and transportation. But several limitations are found during the process of clothing manufacturing 3D technology, these are related to the modelling programs, printing processes, the creation process and the wearing of the clothing. The current manufacturing process of the end-user Danit Peleg includes a farm of standard, one-headed 3D printers, each printing one part of a single garment. The computer-based 3D model of a garment has to be divided into smaller pieces, to fit the size of a 3D printer, prepared for the 3D printing, printed and finally, the individual pieces are sawed together into a single garment. What the end- user wants is to speed up the production process by being able to print much larger pieces of a garment and faster. That will reduce the number of pieces to be printed as well as significantly decrease the time required to put the pieces together. The optimization by speed-up of the production phase is therefore of the utmost importance in delivering the end products to the market.

INDUSTRIAL RELEVANCE

Designers of innovative future

Products are increasingly aware that the breadth of 3D additive manufacturing and new materials offers pragmatically improved technological solutions for many types of industries including clothing. In the future, the 5th Industrial Revolution (AI and Cooperative Systems) will continue today's Industry 4.0. and development will be based on intelligent autonomous robot systems under HPC/Cloud control and Industrial 3D printers as peripherals. 3D Clothing Production by Additive Manufacturing (3D-CPAM) experiment is a brand new optimised, innovative production process with features of flexibility, adaptability, integrability and full programmability but is limited due to the time required to produce a product which significantly decreases the total efficiency of the production .

What are we a part of

CloudiFacturing project

The mission of CloudiFacturing is to optimize production processes and producibility using Cloud/HPC-based modeling and simulation, leveraging online factory data and advanced data analytics, thus contributing to the competitiveness and resource efficiency of manufacturing SMEs, ultimately fostering the vision of Factories 4.0 and the circular economy.

(Expected) ECONOMIC IMPACT

Improving technology, business and social innovation impact

The experiment is expected to have a significant impact on how the fashion is now produced and make it one step closer to a faster and more productive customers- tailored and personalized garments production in less time. Using the proposed process and the multi-bridge 3D industrial printer we envision reducing the overall production cost by factor 2 and the overall production process time by factor 2. Mikrotvornica will enhance its 3D printer with a developed distributed pre-preprocessing and will expand its printer application, not only for the printing community but to a larger market. Danit will improve her business plan and exploit new market segments, especially where fast delivery of personalized garments are expected. The experiment will improve technology, business and social innovation impact.

CLOUD SERVICE

G-CODE generation

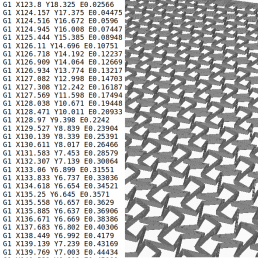

Generating G-CODE from STL file using CURA setup for parallel execution

3D-CPAM Partner

3D printing clothing material

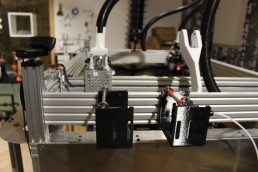

Modax3D printer we are using has usable volume of 550 x 550 x 900 mm, which is composed of two separate gantries with two print heads, allowing for simultaneous printing of multiple objects, or printing of large objects complete garments at much faster than a single-head 3D printer.

NEWS

News about the project and 3D technology

PAPER PUBLISHED: Improving 3D printing of garments by using HPC Cloud

Authors: Tomić, Draško; Davidović, Davor; Šubić, Tomislav; Mesarić, Josip; Skala, Karolj (2020) Improving 3D printing of garments by using HPC Cloud. In: Skala, Karolj, (ed.) MIPRO 2020 43rd International Convention. Rijeka, Hrvatska, Croatian Society for Information, Communication and Electronic Technology – MIPRO, pp. 249-252 .

ABSTRACT

3D garment printing is a technology that is experiencing rapid development, and more and more garments are being printed on 3D printers. Advanced processes such as Selective Laser Sintering and PolyJet 3Dprinting are used. However, 3D printing of clothes still experiences some disadvantages, of which the biggest is the slow 3D printing speed and usually a small printing area of3D printers. The novel, large multi-head printers can significantly increase the printing speed, but such printers require an additional step to prepare given 3D models that increase. However, pre-processing time grows exponentially with the number of printer heads, therefore computer resources that exceed the capabilities of a single workstation are required to prepare a printout. This implies the use of HPC resources, and because of its flexibility, lower cost and ease of use, HPC Cloud is the optimal platform for such jobs. We have shown that the structure of these jobs fits perfectly in the HPC Cloud environment.

Contact

cir@irb.hr

Office

Ruđer Bošković Institue

Bijenička 54, 10000 Zagreb

CROATIA